Sales sheet

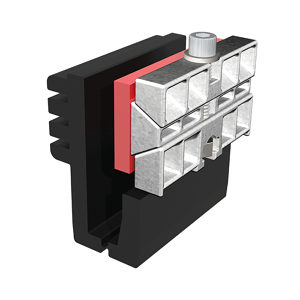

PanelGrip®2 Aluminum Dry-Glaze Base Shoe

To add to cart, choose from the options below.

PanelGrip®2 facilitates the quick assembly of structural glass railing without messy fillers or special tools resulting in significant savings in labor and shipping costs.

| Product # | Type of Mounting | Base section hole drilling patterns | Length | Packaging format |

|---|---|---|---|---|

| HRTV0070132210 | Face Mount | Side Drilled | 3.05 m* | Length of 10 linear foot |

| HRTV0070132220 | Face Mount | Side Drilled | 6.1 m* | Length of 20 linear foot |

| HRTV0079132210 | Floor Mount | Counter Bore | 3.05 m* | Length of 10 linear foot |

ADVANTAGES AND BENEFITS

* Reduce Labor Costs up to 80% - No setting blocks, no plumbing of glass, no multiple pours of cement, no waiting for cement to cure, no messy clean-up

* Broadest Grip Range of any Dry Glaze System -- Made for range of ½" to 13/16" tempered and laminate glass (12.7 mm to 21.5 mm)

* No Special Tools Required -- All you need is an Allen wrench for installation or removal

* No Mess -- No mixing and pouring of expansion cement, no running of cement on incline

* Broadest Grip Range of any Dry Glaze System -- Made for range of ½" to 13/16" tempered and laminate glass (12.7 mm to 21.5 mm)

* No Special Tools Required -- All you need is an Allen wrench for installation or removal

* No Mess -- No mixing and pouring of expansion cement, no running of cement on incline

TECHNICAL SPECIFICATIONS

Safety Glass Thickness

12.7 to 21.5 mm

Recommended Location Usage

Interior, Exterior

Finish

Mill Finish

Height

10.5 cm*

Width

70 mm*

Material

Aluminum 6005-T5

Glass Drilling

Not Required

Category

Base Shoes

Disclaimer

Measures shown with an asterisk (*) have been converted as per your preference. These are not the official measures. To view the measures specified by the manufacturer, click here.