North American SDS

Loctite 312 Speedbonder Structural Adhesive

Product # AUWL312736

Kit contains both adhesive and primer.

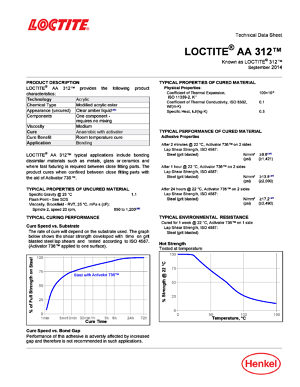

LOCTITE® AA 312TM structural adhesive is an ultra fast setting, two step acrylic amber adhesive that requires no mixing.

312 has a very low viscosity and should be used in conjunction with LOCTITE Primer 736TM to create a tough durable bond on close-fitting parts.

Magnetic bonding structural adhesive.

This illustration is provided for visual reference only.

312 has a very low viscosity and should be used in conjunction with LOCTITE Primer 736TM to create a tough durable bond on close-fitting parts.

Magnetic bonding structural adhesive.

This illustration is provided for visual reference only.

ADVANTAGES AND BENEFITS

-Fast cure (full cure time 24 hr)

-Requires no mixing

-Requires no mixing

TECHNICAL SPECIFICATIONS

Product #

AUWL312736

Finish/Color

Clear Amber

Viscosity

1000 cps

Brand

Loctite®

Features

Ultra Fast Cure

Type

10 ml (0.3 oz) Bond and 41 ml (1.4 oz) Primer

APPLICATION

LOCTITE® AA 312TM typical applications include bonding dissimilar materials such as metals, glass or ceramics and where fast fixturing is required between close-fitting parts.

The product cures when confined between close-fitting parts with the aid of Activator 736TM.

Directions for use:

1. For best performance bond surfaces should be clean and free from grease.

2. To ensure a fast and reliable cure, Activator 736TM should be applied to one of the bond surfaces and the adhesive to the other surface. Parts should be assembled within 15 minutes.

3. Where bond gaps are large (up to a maximum of 0.005" (0.125 mm)), or faster cure speed is required, Activator 736TM should be applied to both surfaces. Parts should be assembled immediately (within 1 minute).

4. Excess adhesive can be wiped away with organic solvent.

5. Bond should be held clamped until adhesive has fixtured.

6. Product should be allowed to develop full strength before subjecting to any service loads (typically 24 to 72 hours after assembly, depending on bond gap, materials and ambient conditions).

- Cure type: heat cure

The product cures when confined between close-fitting parts with the aid of Activator 736TM.

Directions for use:

1. For best performance bond surfaces should be clean and free from grease.

2. To ensure a fast and reliable cure, Activator 736TM should be applied to one of the bond surfaces and the adhesive to the other surface. Parts should be assembled within 15 minutes.

3. Where bond gaps are large (up to a maximum of 0.005" (0.125 mm)), or faster cure speed is required, Activator 736TM should be applied to both surfaces. Parts should be assembled immediately (within 1 minute).

4. Excess adhesive can be wiped away with organic solvent.

5. Bond should be held clamped until adhesive has fixtured.

6. Product should be allowed to develop full strength before subjecting to any service loads (typically 24 to 72 hours after assembly, depending on bond gap, materials and ambient conditions).

- Cure type: heat cure

INCLUDED PRODUCT(S)

The Kit AUWL312736 includes;

1 aerosol accelerator (primer) 736 color amber, 1.4 oz (40g)

1 anaerobic adhesive AA 312 clear amber color, 10 ml

1 aerosol accelerator (primer) 736 color amber, 1.4 oz (40g)

1 anaerobic adhesive AA 312 clear amber color, 10 ml

IMPORTANT INFORMATION

312 adhesive;

-Boiling point/range; > 149°C (> 300.2°F)

-Flash point; > 93.4°C (> 200.12°F) Tagliabue closed cup

-VOC content; < 3%; 30 g/l

736 accelerator;

-Boiling point/range; 77 - 82°C (170.6 - 179.6°F)

-Flash point; 76°C (168.8°F)

-VOC content; 95.6%; 1,243 g/l EPA Method 24

This illustration is provided for visual reference only. Actual product may differ from the illustration.

-Boiling point/range; > 149°C (> 300.2°F)

-Flash point; > 93.4°C (> 200.12°F) Tagliabue closed cup

-VOC content; < 3%; 30 g/l

736 accelerator;

-Boiling point/range; 77 - 82°C (170.6 - 179.6°F)

-Flash point; 76°C (168.8°F)

-VOC content; 95.6%; 1,243 g/l EPA Method 24

This illustration is provided for visual reference only. Actual product may differ from the illustration.